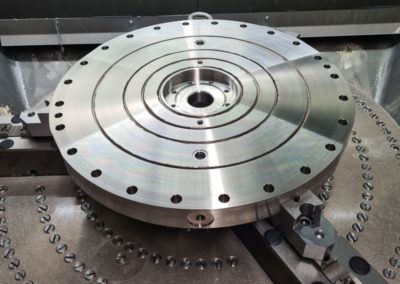

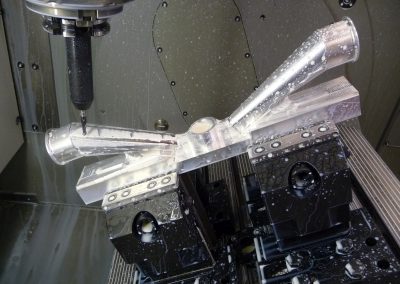

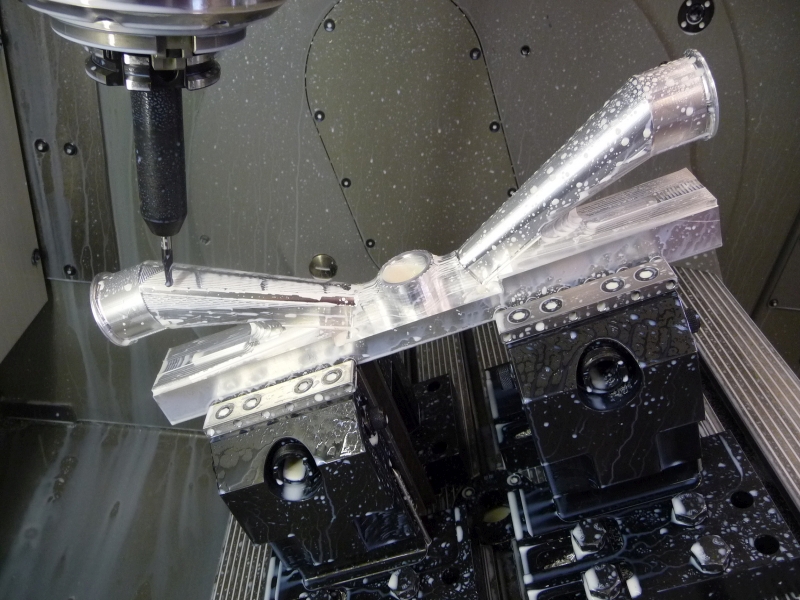

Job work production – Manual manufacturing

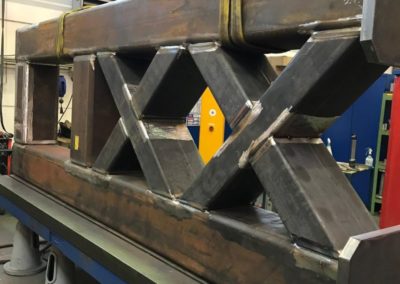

Welding:

In the welding area, manual arc welding, TIG, MIG and MAG welding are used to weld unalloyed, low-alloyed and high-alloyed steels, aluminum, high-nickel materials and other special materials.

Single parts and series can be produced according to customer requirements. The welding staff is certified according to ISO 9606 and the testing staff is certified in accordance with EN 473.

Other certificates to which we are authorized to fabricate are DIN 18800-7 Class E, EN 1090-2 EXC4, EN 1090-3 EXC4 and AD 2000 leaflet HP0.

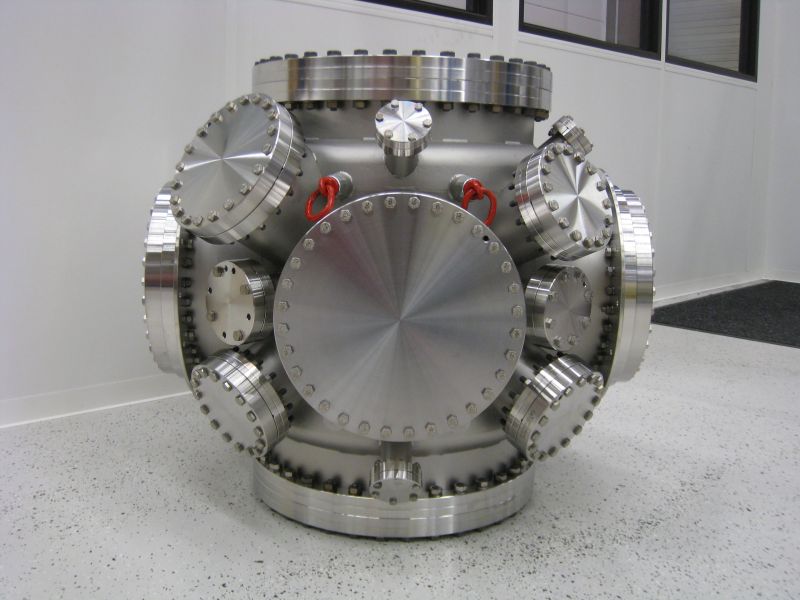

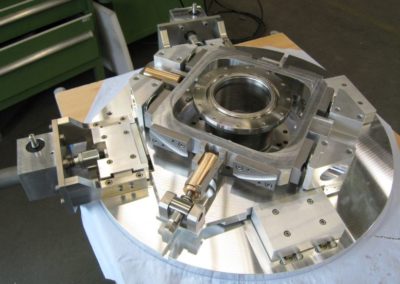

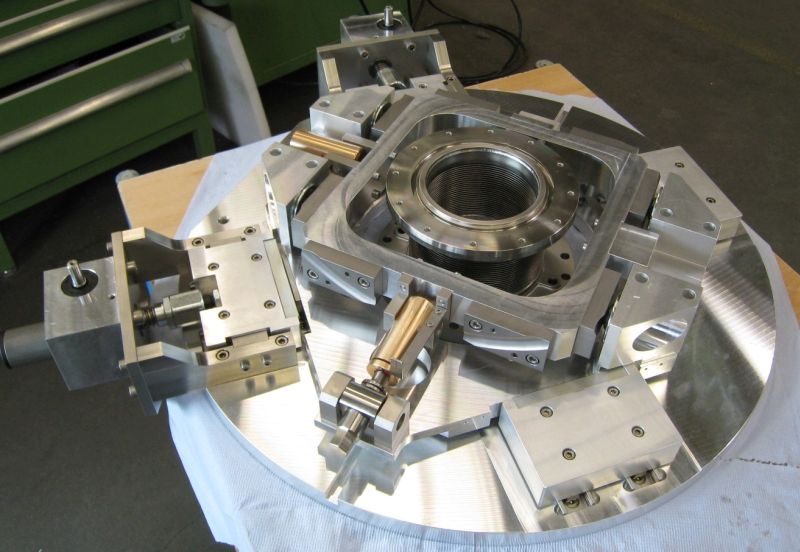

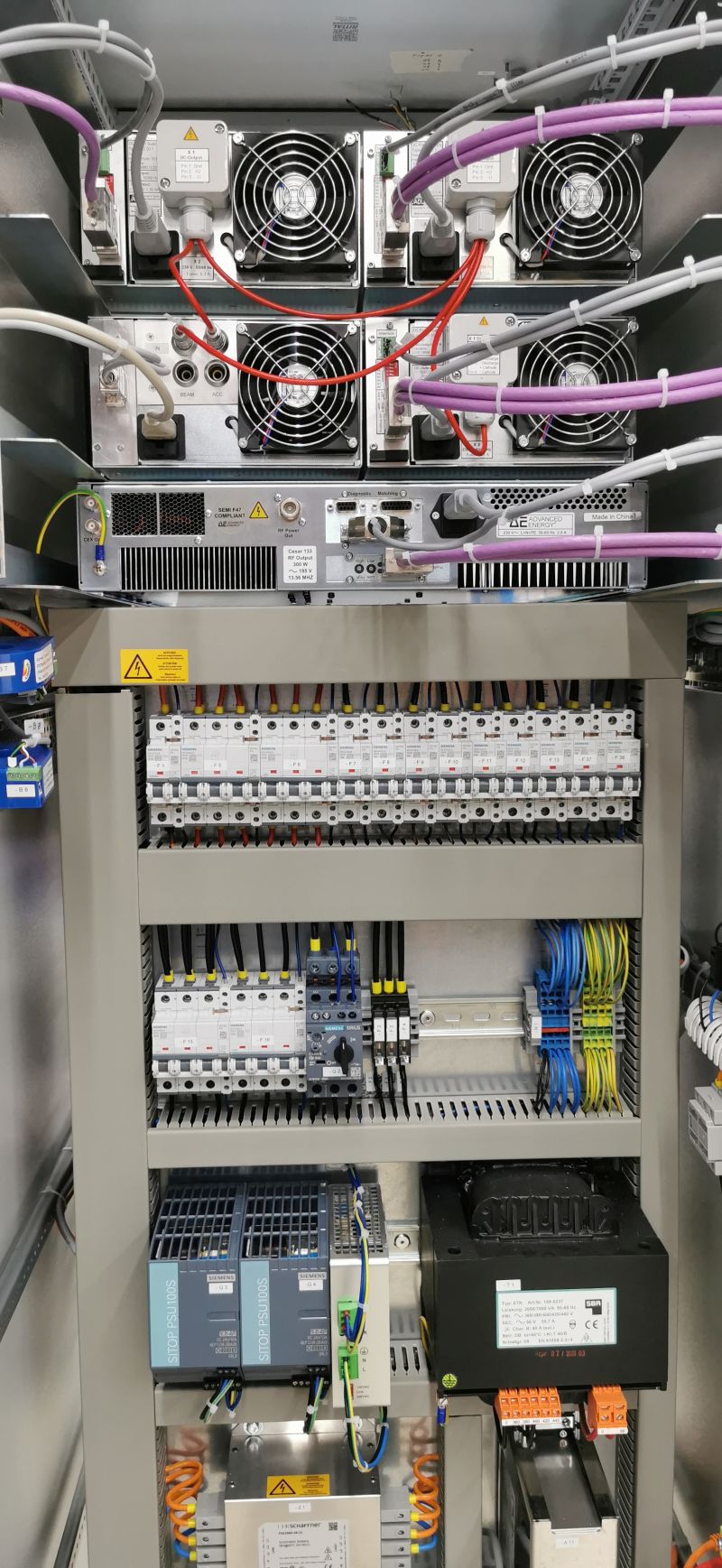

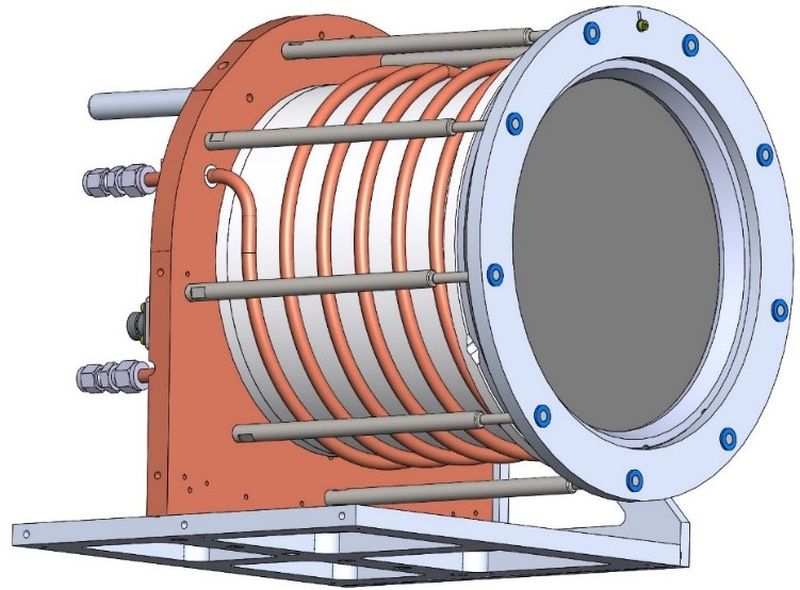

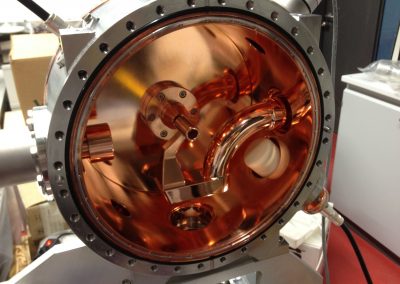

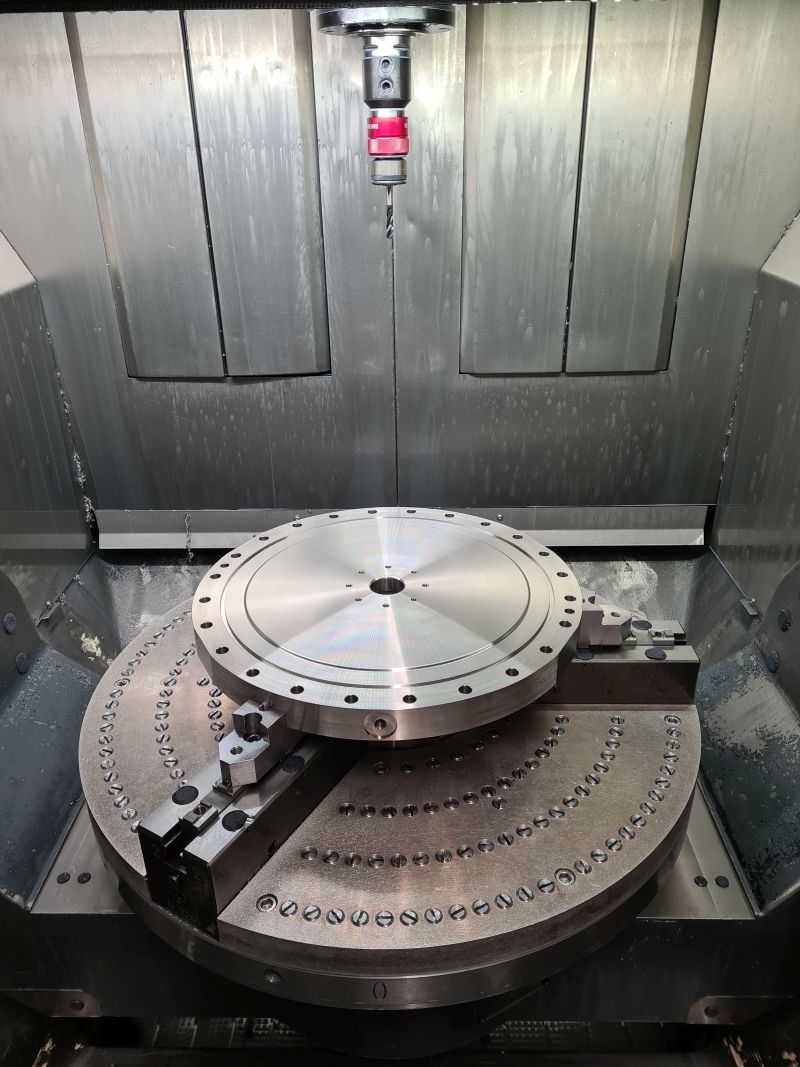

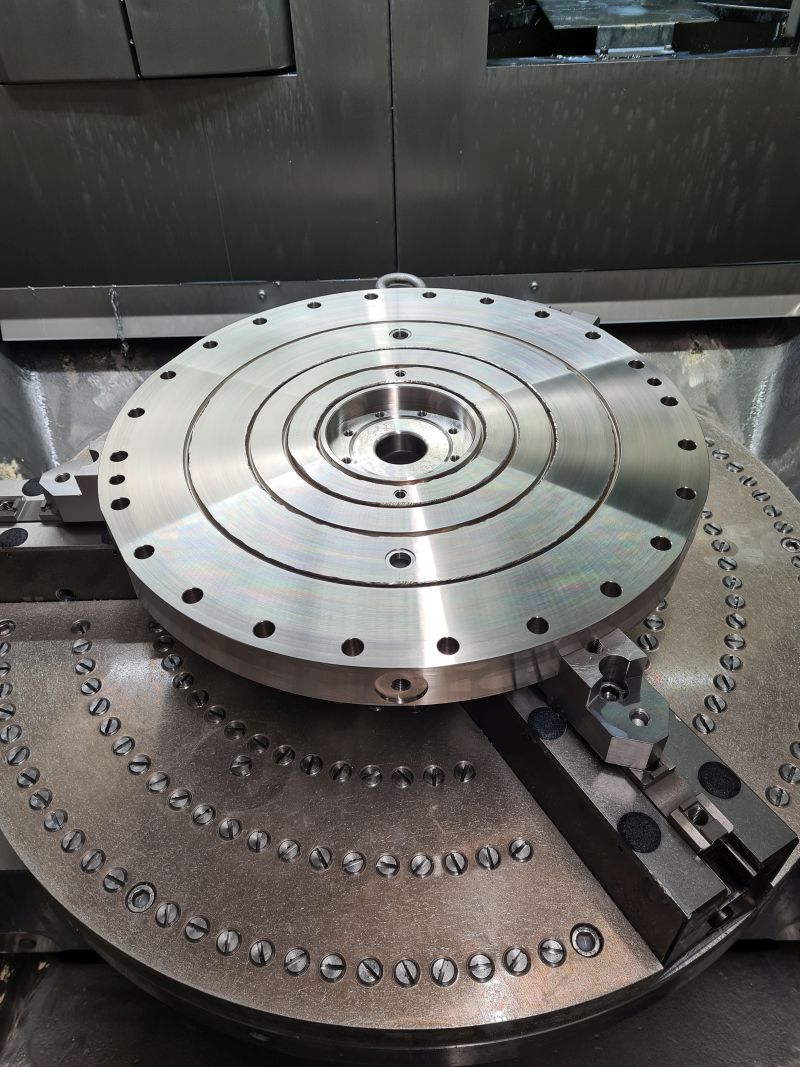

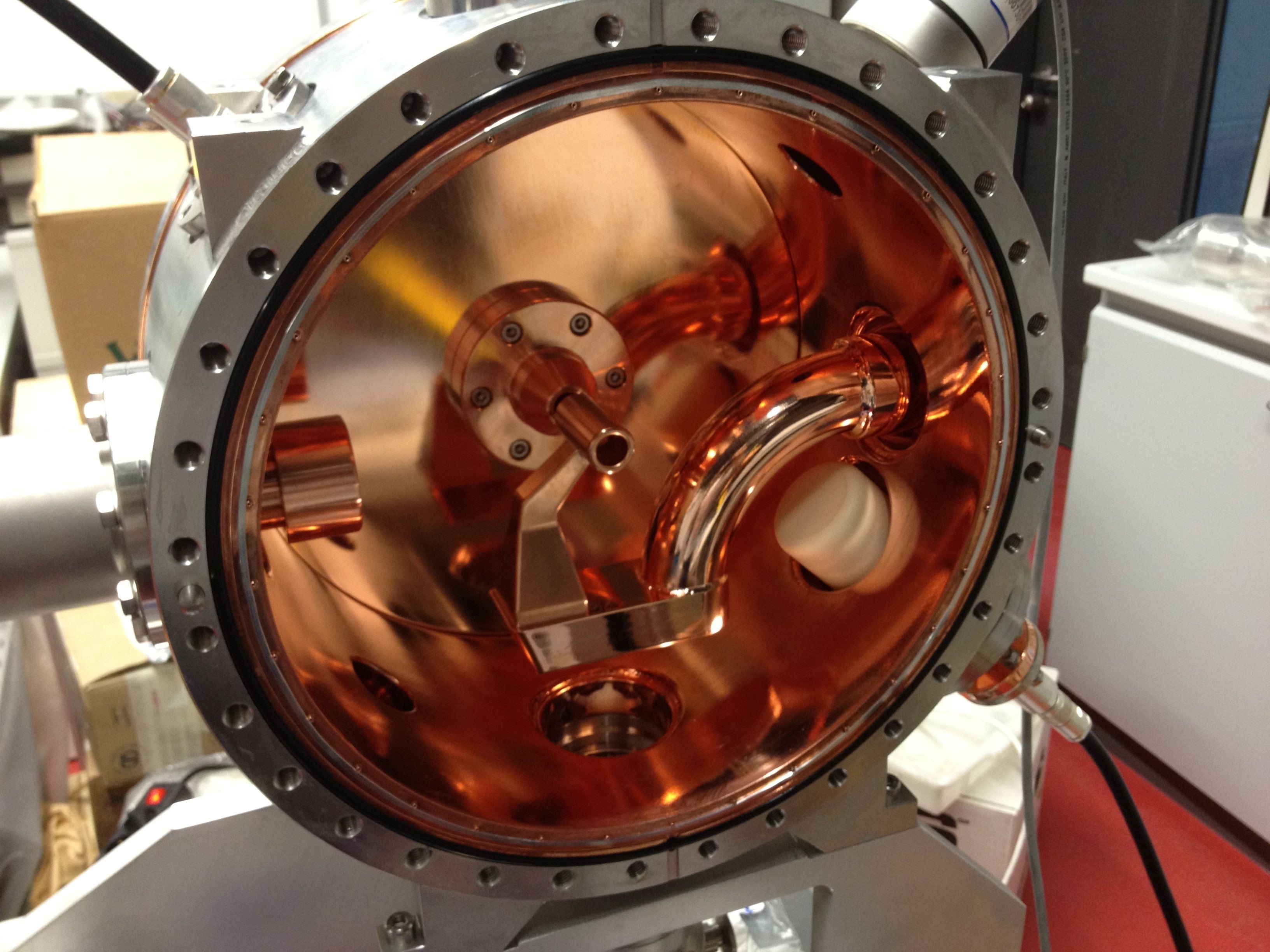

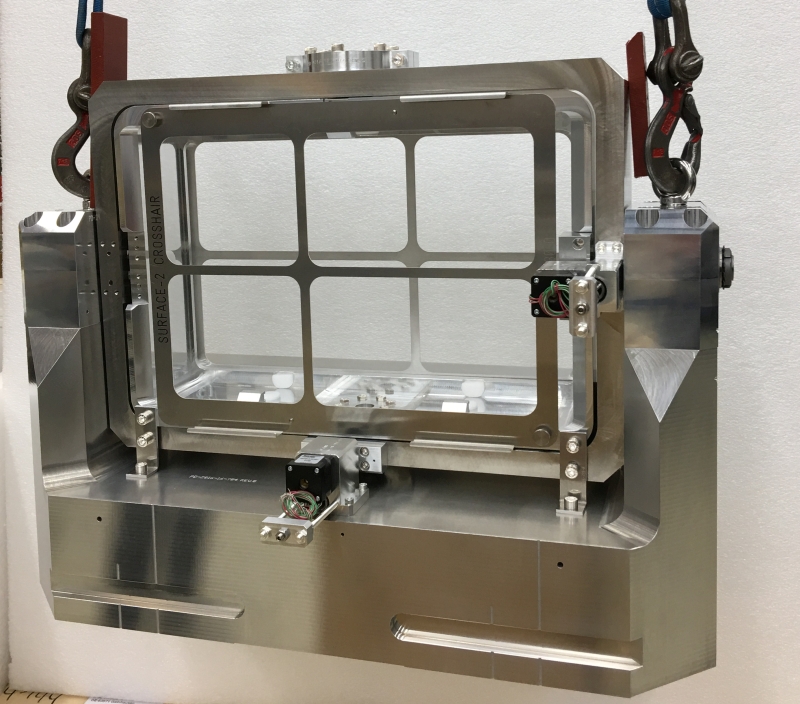

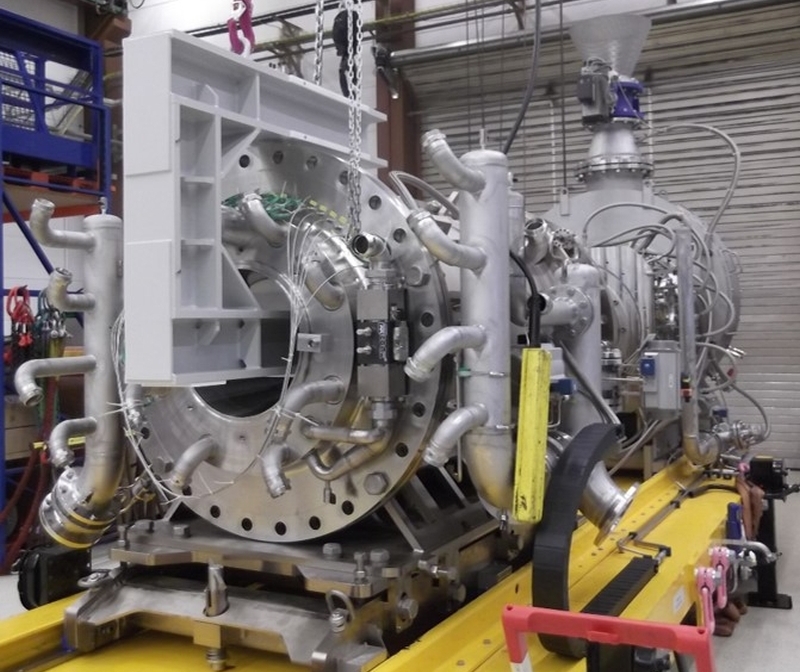

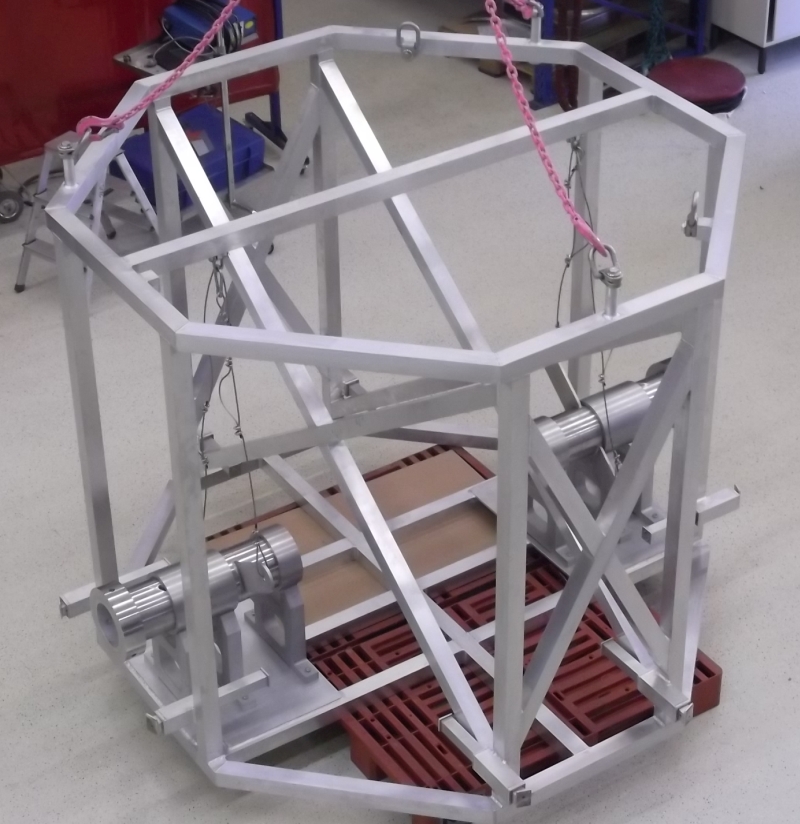

Assembly of components:

On more than 400m2 we assemble smaller sub-assemblies, single parts or series, modules or complete plants, including electrical work and necessary testing.

We hope this article has aroused your interest and look forward to your feedback. If you have any questions about an area, please feel free to contact us and we will get back to you.