Hochtechnologie – Made in Germany

NTG –

Neue Technologien GmbH & Co. KG

Innovative Konzepte für Ihre Anwendung –

von der ersten Idee zum fertigen Produkt, alles aus einer Hand.

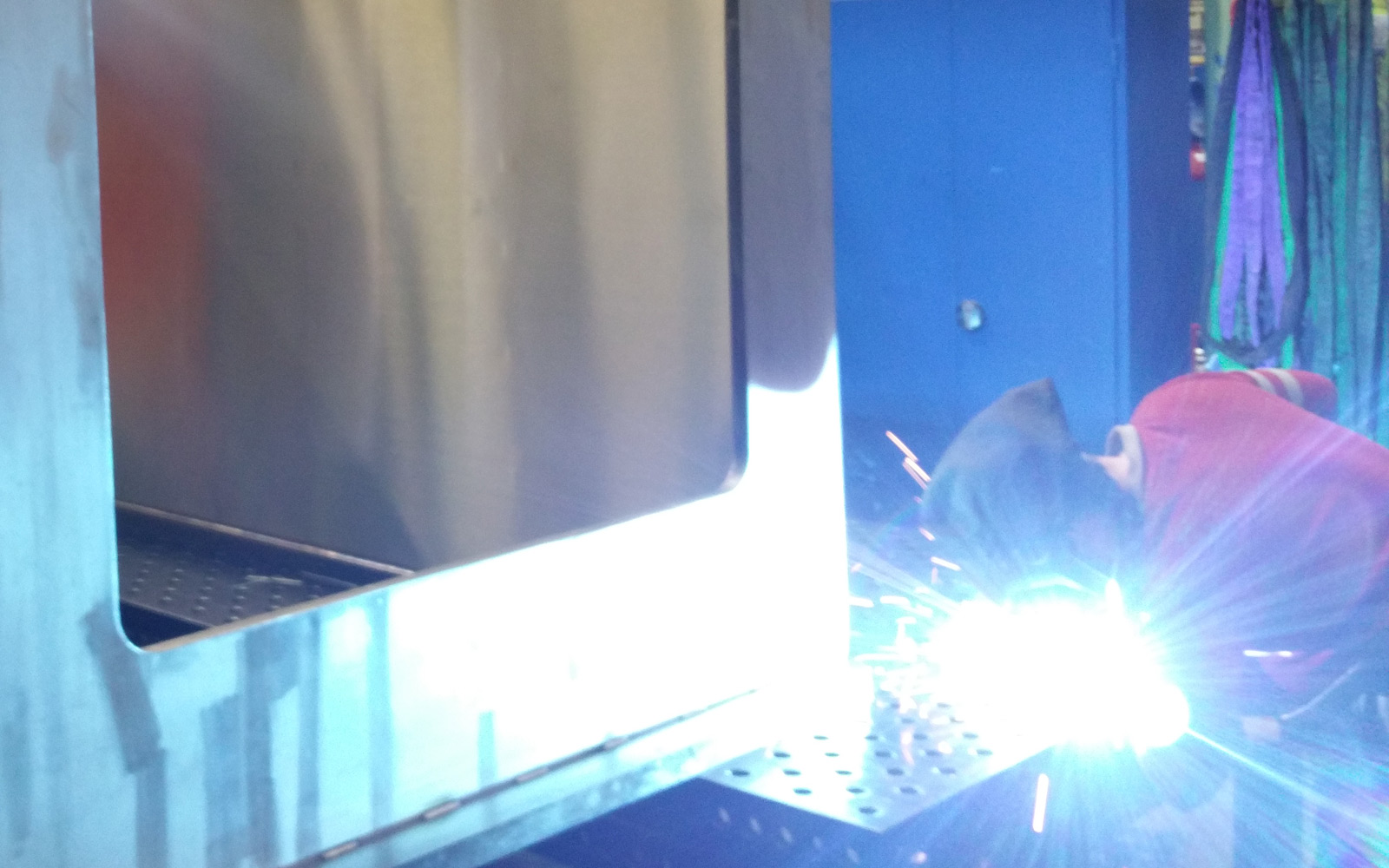

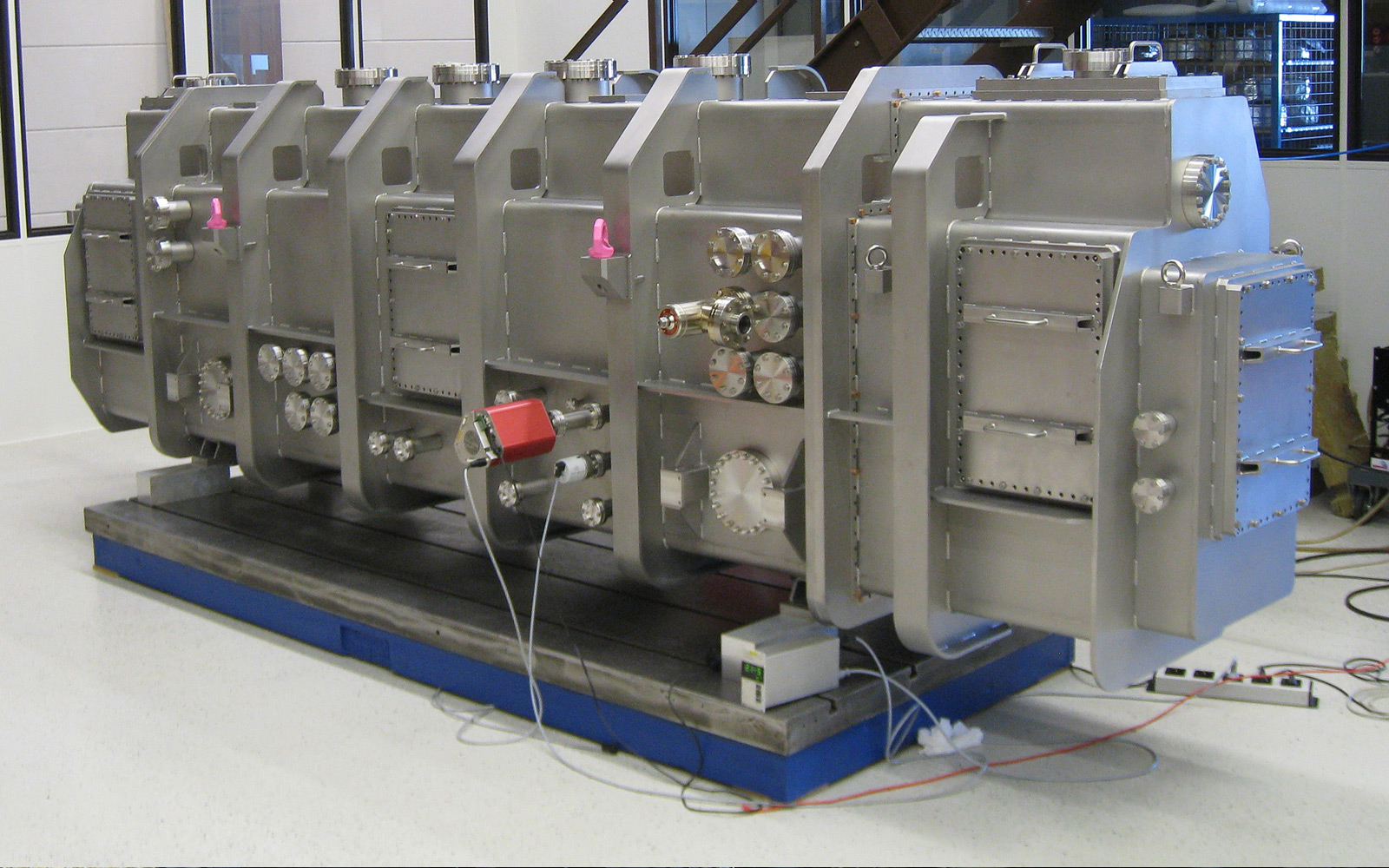

NTG Neue Technologien GmbH & Co. KG ist ein weltweit agierendes mittelständisches Maschinenbau-Unternehmen mit Sitz im Zentrum der Europäischen Union. Made in Germany ist bei uns keine Floskel. Unser Leistungsspektrum reicht von der Fertigung einfacher Einzelteile bis zu komplexen verfahrenstechnischen Anlagen. Von Konstruktion über Fertigung bis zur Inbetriebnahme erfolgt bei uns alles aus eigener Hand. Auch in der Lohnfertigung sind wir Ihr kompetenter Partner.

Aktuelle Neuigkeiten:

Fußballmatch der NTG Mitarbeiter

Vergangenen Freitag lieferten sich unsere Mitarbeiter aus der Verwaltung und der Werkstatt ein spannendes und stellenweise sehr lustiges Match, als sie in einem vom Betriebsrat „angezettelten“ Fußballspiel gegeneinander antraten. Freundlicherweise stellte uns der SV...

NTG Mitarbeiter stellt Weltrekord auf!

Wir gratulieren unserem Werksstudenten Marcel Paul zu seinem Weltrekord für die „höchste Geschwindigkeit auf einem modifizierten Bobby Car mit E Antrieb“ Nach wochenlanger Vorbereitung und Modifizierung seines Rennboliden, raste er mit einer unglaublichen...

NTG präsentiert Ankunftszeitmonitore auf der IBIC 2023 in Kanada

Treffen Sie NTG auf der diesjährigen IBIC2023 Strahldiagnose Konferenz vom 10. bis 14. Sept. 2023 in Saskatoon Kanada am Stand Nr. 10. Erfahren Sie mehr über unsere jüngsten Entwicklungen bei sogenannten Ankunftszeitmonitoren für Elektronenbunche mit zeitlicher...

Ionenstrahlplanarisieren von diamantgedrehten NiP Oberflächen

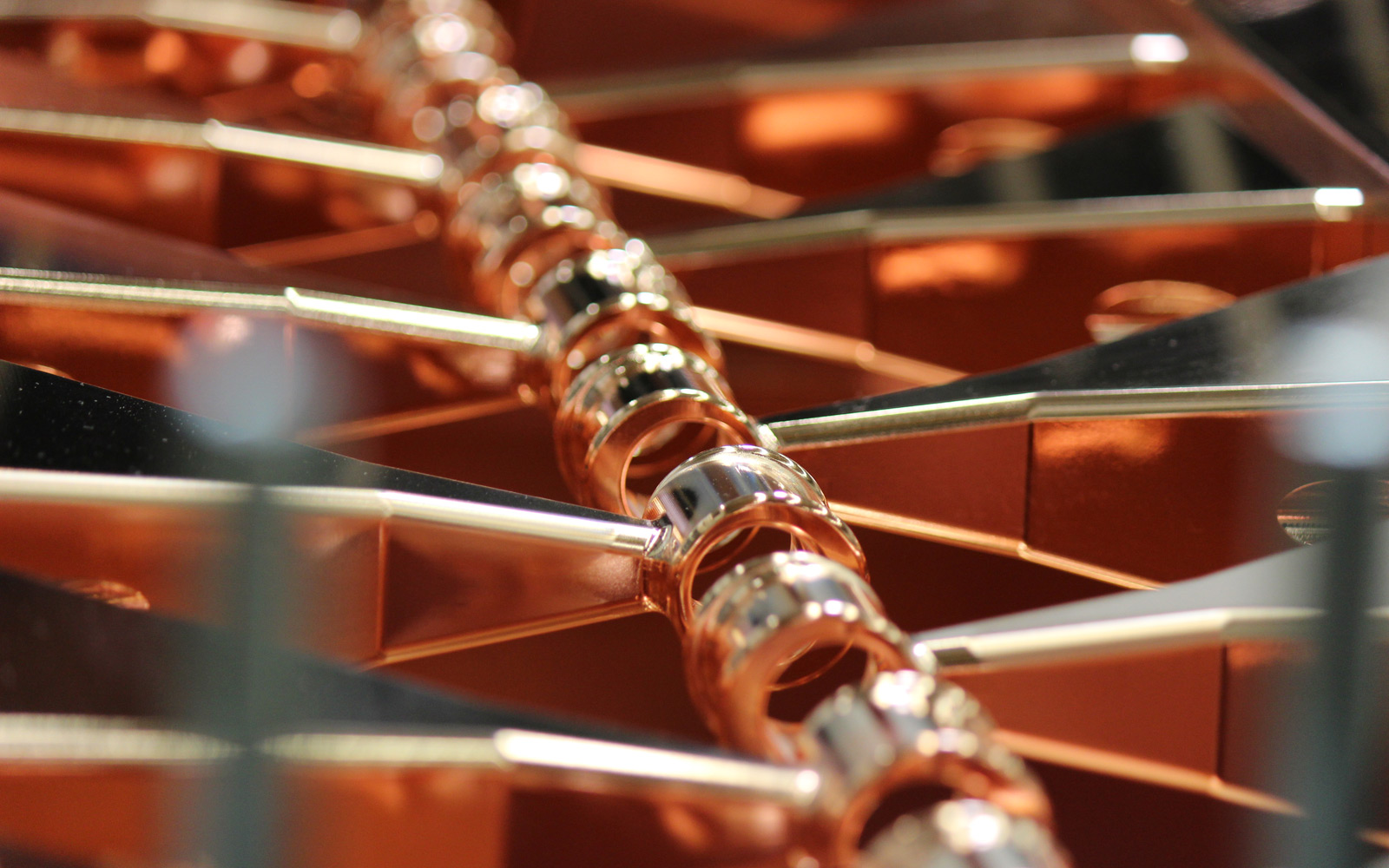

Seit mehr als 30 Jahren beschäftigt sich die NTG neben anderen Produktbereichen aus Wissenschaft und Forschung mit der Entwicklung und dem Vertrieb von Ionenstrahl-Bearbeitungsanlagen zur Herstellung von ultrapräzisen ebenen und gekrümmten Oberflächen optischer...

NTG fertigt Teile für E-Bobby-Car Weltrekordversuch

Unser Werkstudent Fachrichtung Elektrotechnik, Marcel Paul, der mit einem „normalen“ Bobby-Car bereits einen Geschwindigkeits-Weltrekord aufstellte, plant nun einen neuen Rekord mit einem elektrisch angetriebenen Bobby-Car. Hierfür wurde er wieder tatkräftig von...

Nehmen Sie sich ein paar Minuten Zeit und lernen Sie unsere Produkte und Leistungen kennen. Fordern Sie uns heraus, unsere Ansprechpartner stehen Ihnen gerne jederzeit bereit.