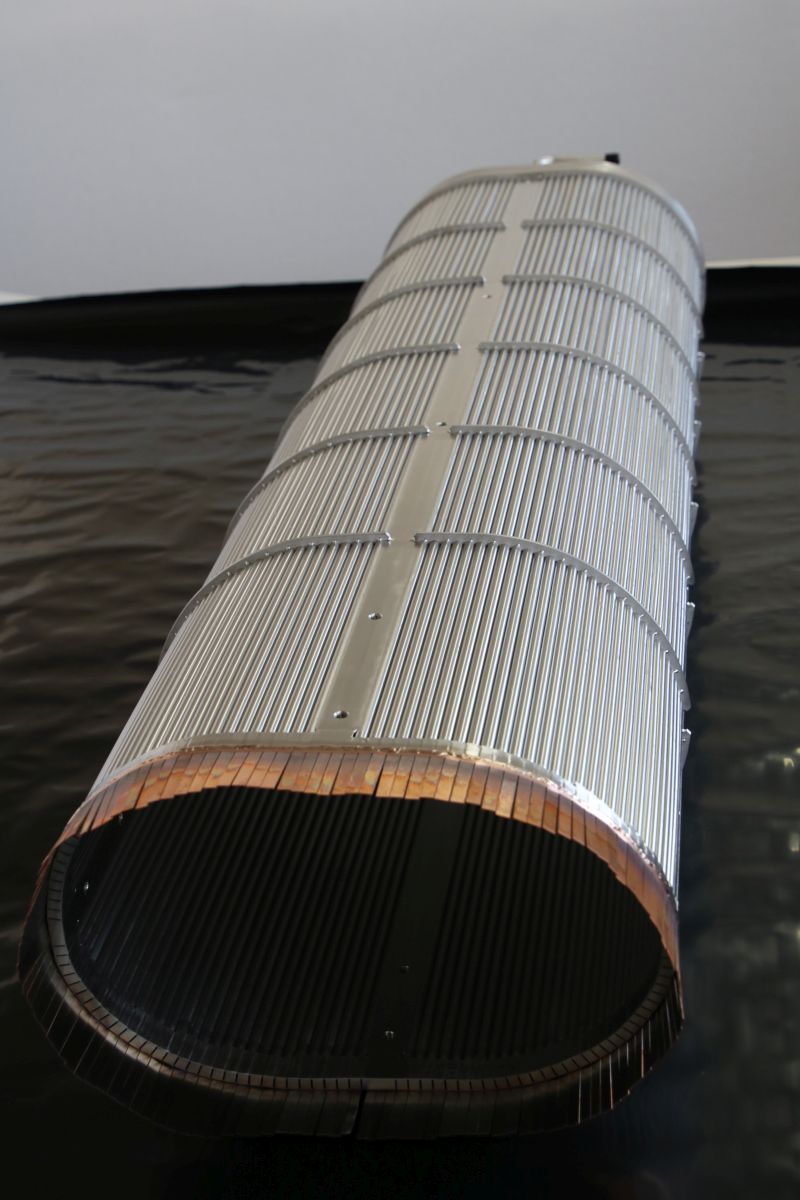

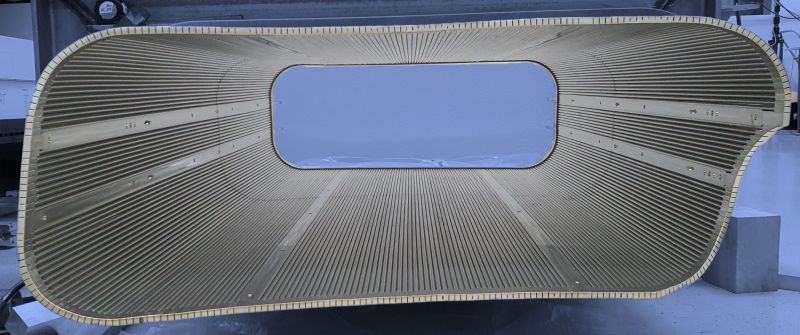

NTG develops and manufactures components to complete the Wendelstein 7-X at the Max Planck Institute for Plasma Physics in Greifswald. In this experimental facility for researching nuclear fusion technology, built on the principle of the stellarator, plasmas are enclosed with superconducting coils and heated to 100 million degrees Celsius. All elements coming into thermal contact with the plasma must be cooled with water. This also includes the ports, a significant component group of the stellarator. The ports connect the plasma vessel with the outer vessel; via these accesses, the plasma is observed and supplied. To prevent the ports from heating up inadmissibly due to thermal radiation from the plasma, and thus the cryogenic chamber, they must be protected with water-cooled linings. These linings – a total of 86 so-called “portliners” – were developed, built and tested by NTG.

The technical challenge was the combination of high power input, tight tolerances and use in ultra-high vacuum. The cooling system is designed for a power input of 50 to 100 kW/m2 and operates according to the heat exchanger principle: The cold water runs in four millimeter-thin tubes, which in turn are located in eight millimeter-thick tubes. The water flows back in the space between these two pipes. This design allows the different geometries of the nozzle linings – round, rectangular or oval – to be shaped and manufactured precisely to fit the narrow installation spaces of 15 to 20 millimeters.