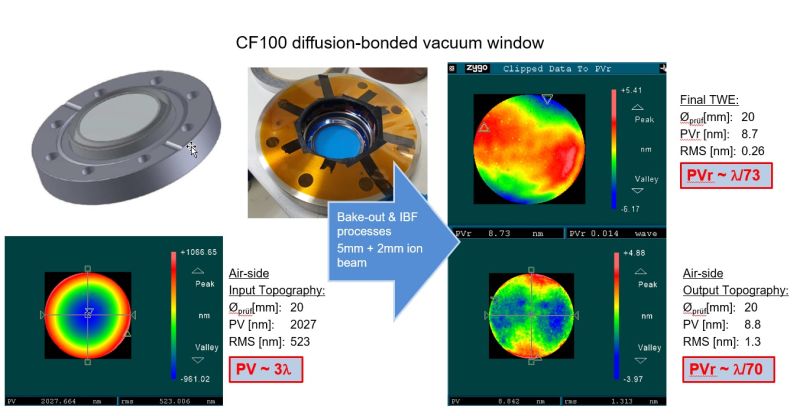

Diffusion-bonded vacuum windows can exhibit severe deformation and stress after finishing. However, special applications require a high optical quality with diffraction-limited resolution. Mechanical post-processing or polishing of the optical window is not possible due to the flange geometry. In addition, the difficulty arises that additional stress can be built up after a bake-out process in the application, which will further deform the optical glass. We have developed a special process by which the stress of the window is drastically reduced and the surface topography as well as the transmitted wavefront can be optimized in the range from PV 2µm to PV 8.8nm (lambda/70). Later bake-out during the final optical application results in almost no further deformation. This is achieved by an alternating bake-out process with multi-stage IBF processing using a 5mm ion beam cross section and final fine correction with 2mm cross section.

For more information on IBF contract manufacturing please contact Dr. David Schäfer.