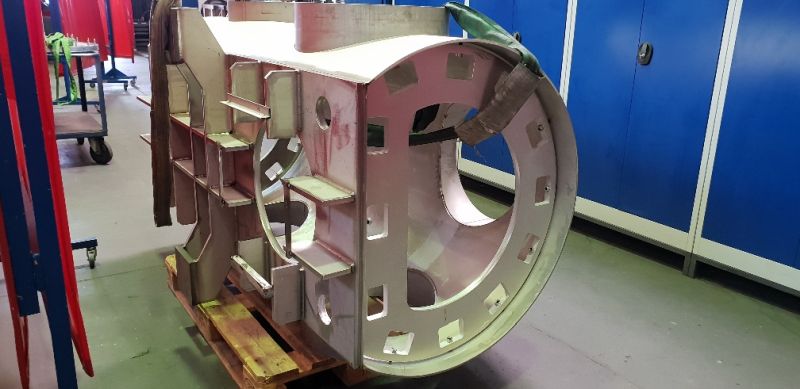

Manufacturing of vacuum components, cleaning and installation on site

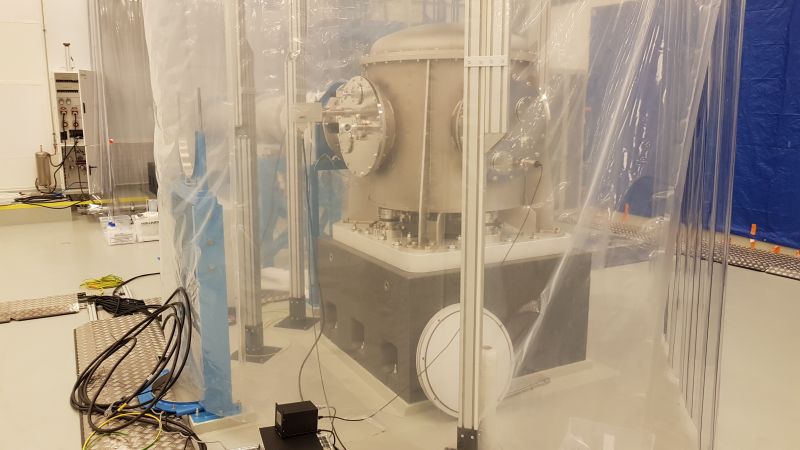

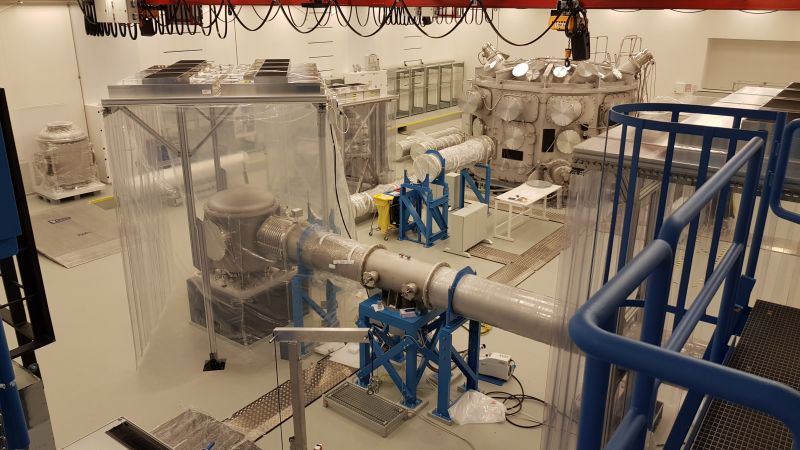

The system consists of 22 mirror chambers mounted on a steel frame or granite block, optical tables (breadboards) for each chamber which are mechanically decoupled and independently adjustable in height, approx. 107m of DN500 pipe, various vacuum slides, steel frames, pipe supports, granite blocks and a complete vacuum system.

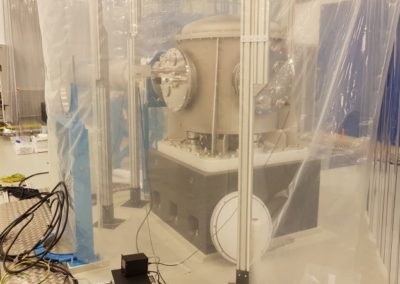

All vacuum components were cleaned under clean room conditions to avoid any particles on the surface.

The assembly of the frames and granite blocks took place under ISO7 cleanroom conditions followed by the assembly of the individual components under ISO5 conditions segment by segment.

We are looking forward to your inquiry