NTG manufactures parts for e-bobby car world record attempt

Our electrical engineering student, Marcel Paul, who has already set a world speed record with a “regular” Bobby-Car, is currently planning to attempt a new record with an electrically driven Bobby-Car. Once again, he was actively supported by his colleagues and the well-equipped machine park of NTG.

Almost everything for the e-Bobby Car was manufactured at NTG except the bobby car body, the motor, the battery and some standard parts.

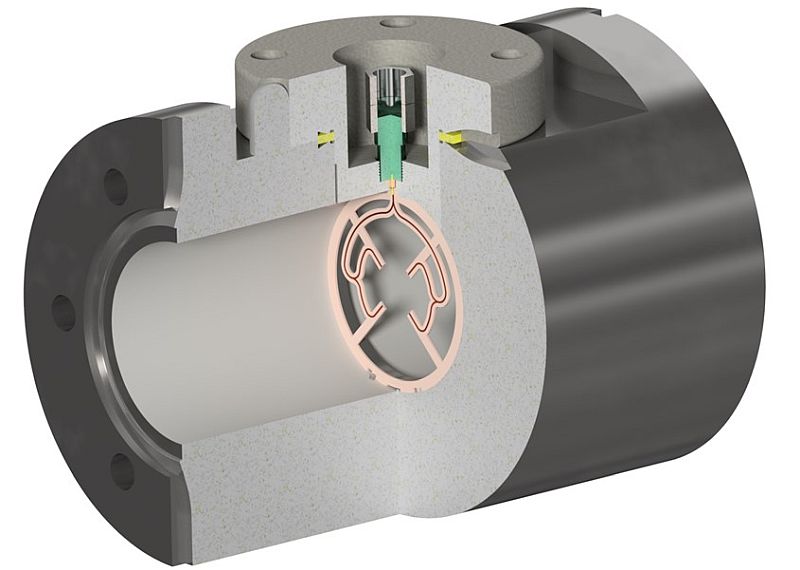

The vehicle was designed by Marcel Paul in the SolidWorks 3D CAD programme. This was followed by the manufacturing drawings.

After that, the processing steps began within the company:

- starting with the base plate and the preliminary work on the individual components on the StM Waterjet 3020 Premiumcut 3D/68 waterjet cutting system.

- the semi-finished products were then machined on different machines:

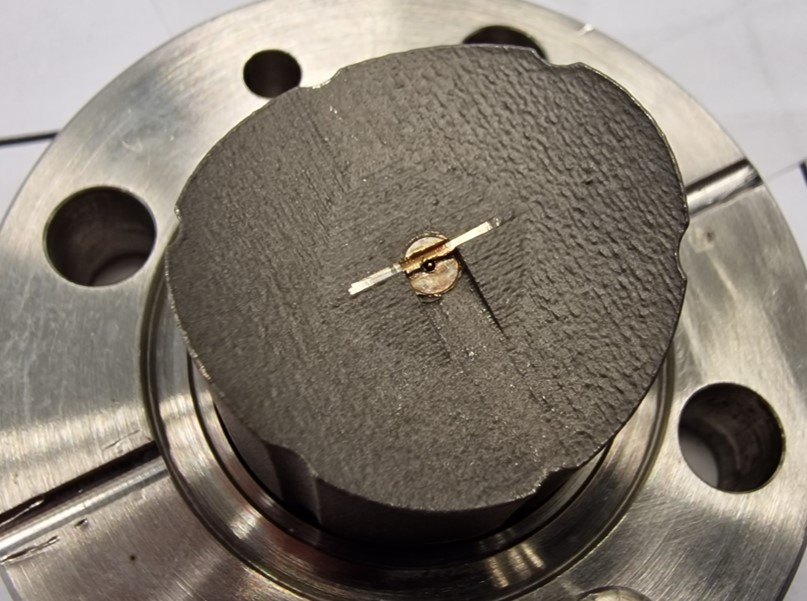

- Turned parts such as the rims, the drive shaft and the front axles were produced on the Okuma LB 400.

- Milled parts were manufactured on the machines Deckel Maho DMU 80, Deckel Maho DMC 160 U, Maho 800 and Maho MH500-W2.

- quality control was carried out after completion.

- the mechanical lightweight chassis was assembled in the mechanics department.

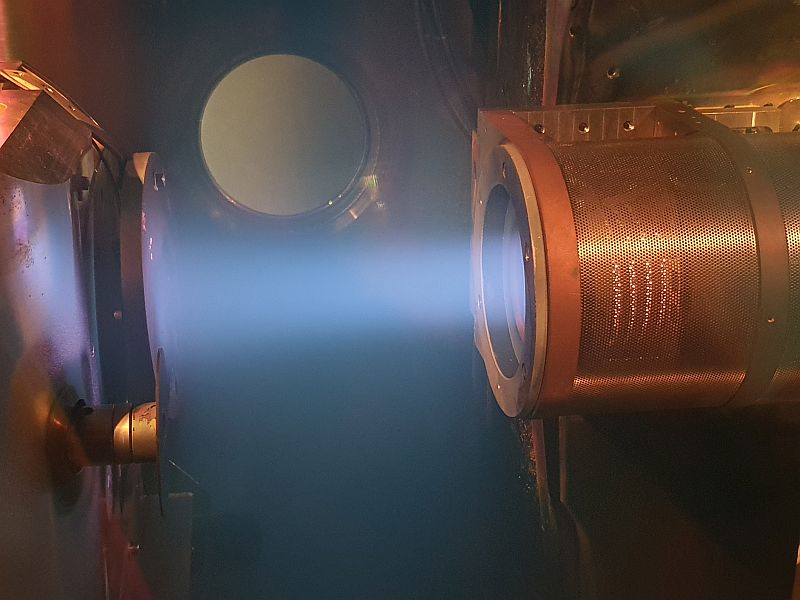

- a first test without the motor followed. The motor and battery were manufactured externally during this time.

- after the motor and battery arrived, they were installed and wired in the electrical department.

- the vehicle was programmed using software and CAN bus and made ready to be driven.

In a manner of speaking, the vehicle went from drawing board to completion through the entire manufacturing cycle within NTG.