latest News

The Extreme Light Infrastructure – Nuclear Physics (ELI-NP) is an European Centre of excellence for high-level research in ultra-high intensity laser, laser-matter interaction and secondary radiation sources with unparalleled possibilities worldwide. The laser intensities within the ELI-NP facility will go beyond the intensity of current state-of-the-art lasers by an order of magnitude.

Because of its unique characteristics, this multidisciplinary facility will provide new opportunities to study the fundamental processes unfolded during light-matter interaction. ELI-NP will create a research and development platform, where applied research will play a major role and applications for the benefit of society will be dynamically promoted.

More Information:

The ELI-NP research facility is located in Magurele, Ilfov County, Romania. ELI-NP houses a high-power laser system (HPLS) with two 10-PW beams and a Gamma Beam System (GBS) producing a gamma beam with parameters far beyond those produced by by the present state of the art machines.

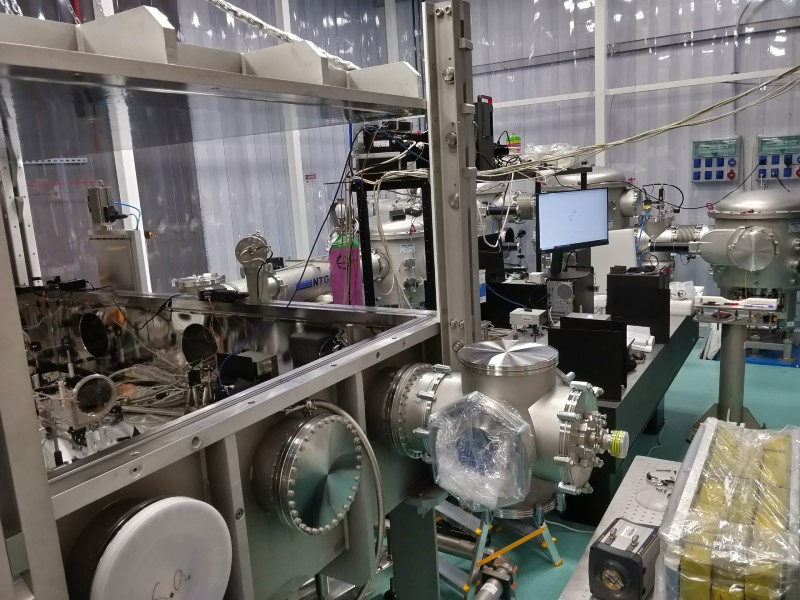

The VEBTVS100 system shown in the film (vacuum chambers, beam transport system, pump supports, control and vacuum technology) was designed, manufactured, delivered, installed and commissioned by NTG for ELI-NP.

The Role of VEBTVS100 in the ELI-NP Research Facility:

The ELI-NP laser system has two outputs at high repetition rates (10Hz) for 100TW power of the ultrashort pulses. In order to steer and focus the 100 TW laser beams, mirrors mounted in micrometric precision positioning systems (translation and rotation) are required. The mirrors and the positioning system must work in vacuum, in low vibration and constant temperature conditions, as well as high cleanness in order to avoid mirror surface contamination. The vacuum enclosures and beam transport system manufactured by NTG house several mirrors and various experimental equipment (target systems, diagnostics for laser beam and produced radiation characterization), and the modular design of the vacuum system allows further extension according to the needs of future experiments.

The first experiments at the international research centre Extreme Light Infrastructure – Nuclear Physics (ELI-NP) for the study of the interaction of high-power laser pulses with matter have already started on 18.03.2020 in Romania.

The experiment aims to study the nonlinear optical effects in solid materials in order to shorten the duration of laser pulses for nuclear physics research and related applications.

This first experiment is the result of the planning and research carried out by the ELI-NP team in the last four years, together with the team of Professor Gerard Mourou, winner of the Nobel Prize for Physics in 2018, from Ecole Politechnique, IZEST, France.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationMYRRHA protons successfully accelerated

Our contribution to the EU funded project MYRTE for the conversion of radioactive fission residues consisted in the technical design of a 4 m long RFQ structure to accelerate protons to an energy of 1.5 MeV for further acceleration in subsequent structures. This RFQ has now been successfully tested with beam.

Further informations can be downloaded here::

https://www.sckcen.be/en/news/myrrha-protons-accelerated-successfully

NEW – The IBF 5 …

… is the smallest ion beam figuring machine from NTG. Optical components from 0.5mm to 5mm diameter can be processed here in highest precision. Operating at up to 3kV, the newly developed ion source based on an RF excitation and pentode extraction system can be used with variable beam diameters of approx. 40-150μm for both shape correction and shaping.

Further informations can be downloaded here: IBF5

„Pushing the limits: 40µm Ion Beam Processing“

Listen to Dr. David Schäfer on this topic at the 10th Wetzlar Autumn Conference on Wednesday, 30.09.2020.

You can find the complete program of the conference here: Herbsttagung_2020

This was one of the few events that could take place in 2020.

“New technologies in toolmaking – Ion Beam Figuring”

was the title of the presentation given by Dr. David Schäfer at the seminar “Replicative Manufacturing of Glass Optics”, which was organized by Photonics HUB GmbH in cooperation with the Fraunhofer IPT. More information about this training can be found here: Replikative Fertigung von Glasoptiken

The seminar is expected to be held again in June 2021.

“First aid for children – learning to help by playing”

What do I do in case of burns, a tick bite or poisoning? And above all: How can I help others in an emergency? The sponsoring association of the Christoph 2 air rescue station in Frankfurt am Main e.V. and the KIM publishing group have set themselves the goal of answering these questions in a way that is suitable for children and have published an easy-to-understand coloring and workbook for girls and boys of elementary school age. We think: This is a good thing!

With the support of many local companies, the painting and workbooks can be distributed free of charge to elementary school children in the Main-Kinzig district. A commitment that we are very happy to support.

Would you like to learn more about the project? You can find more information here: www.verlagsgruppe-kim.de

Picture credits: Abb. @ Verlagsgruppe-KIM

The Caritas Box …

… is a campaign by Caritas and INTERSEROH Product Cycle GmbH. It helps the environment and raises money for projects that support people in need. Since 2006, more than 709,793.88 euros have been raised for local social projects as a result of the campaign.

Around 120 million printer cartridges are used every year in Germany alone. More than 80 percent of them end up in the residual waste after a single use and can no longer be reused. In fact, printer cartridges are not waste, but are ideal for easy reuse – even several times over (as long as they are in perfect condition). The CaritasBox collects all common original printer cartridges from laser and inkjet printers as well as laser copiers and fax machines.

Every institution and every company can be part of it! You can find more information here: http://www.caritas.de/caritasbox

Businesses flourish – we are part of it!

Inspired by the “Main-Kinzig-blüht” nature protection campaign sponsored by the government of Hessen, we began the first step in late summer 2020 with the planting of hedges in 15 different species, which were specifically chosen for the needs of native bird species that will hopefully breed there in great numbers. In addition, with the active help of our first-year apprentices, we have created a wild shrub border for wild bees and butterflies. 200 perennials in over 20 species were planted. Thanks to our shareholder, Mr. Karl Gutmann, who brought several meters of dead wood, not only an insect hotel was created, but a true insect metropolis, which also becomes a living space for small animals.

Click here for the press article

In the coming years, we will continue to ensure that the biodiversity in the business park continues to expand on our 5,600 m2 site. We are already looking forward to the first blooming of the wildflower areas.

You can find more information about this project here: Naturschutzkampagne-Hessen